water jet Cutting

water jet Cutting Services

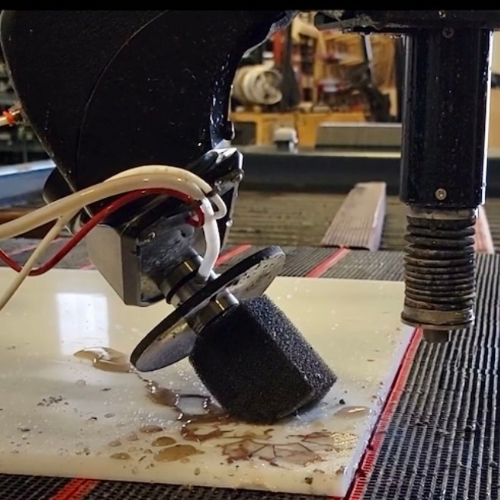

With our Omax 1530 abrasive cutting machine we are now capable of cutting a wide variety of materials. A water jet uses a high-pressure jet of water, or a mixture of water and an abrasive substance. Equipped with a 5-axis cutting head allows JM to cut angles, chambers, and complex geometries. This allows JM to cut parts with tight tolerances which eliminates or reduces machining times.

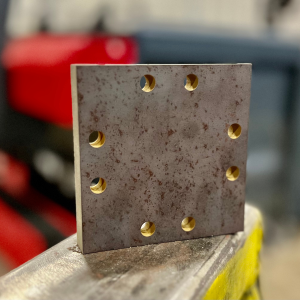

water jet in Action

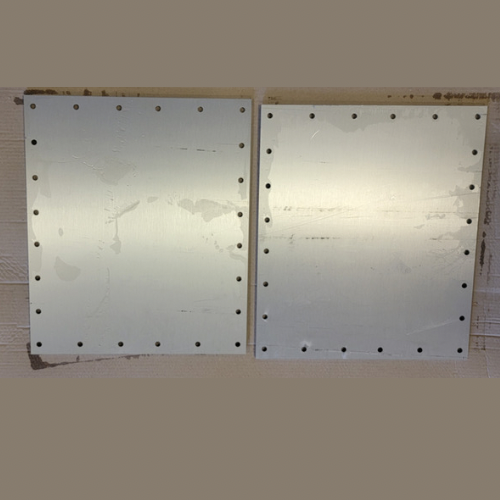

water jet Cutting

- Excellent finish

- Tight tolerance

- No distortion of material structure

- Precision cut quality

water jet Specs

Machine Capabilities

- Allows cutting of any material

- Smooth edge- no heat

- Finish parts or minimal secondary action

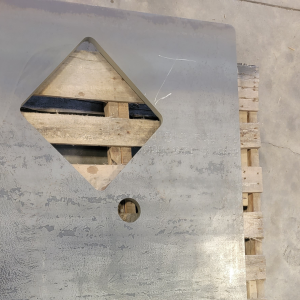

- Can cut complex geometrics

Sample of Items/Exciting Updates

Frequently Asked Questions

What is a water jet?

What is the thickness you can cut?

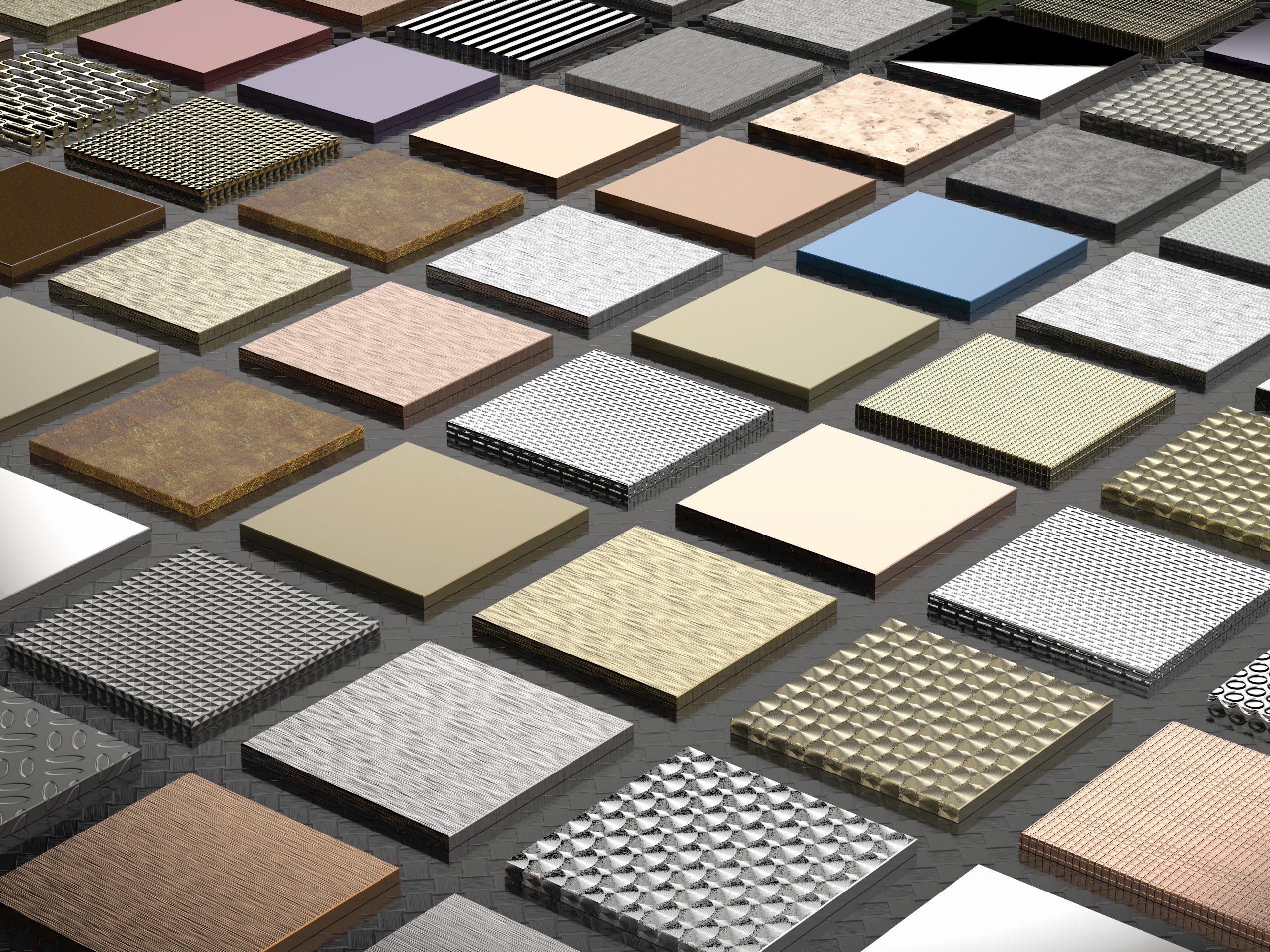

What materials can you cut?

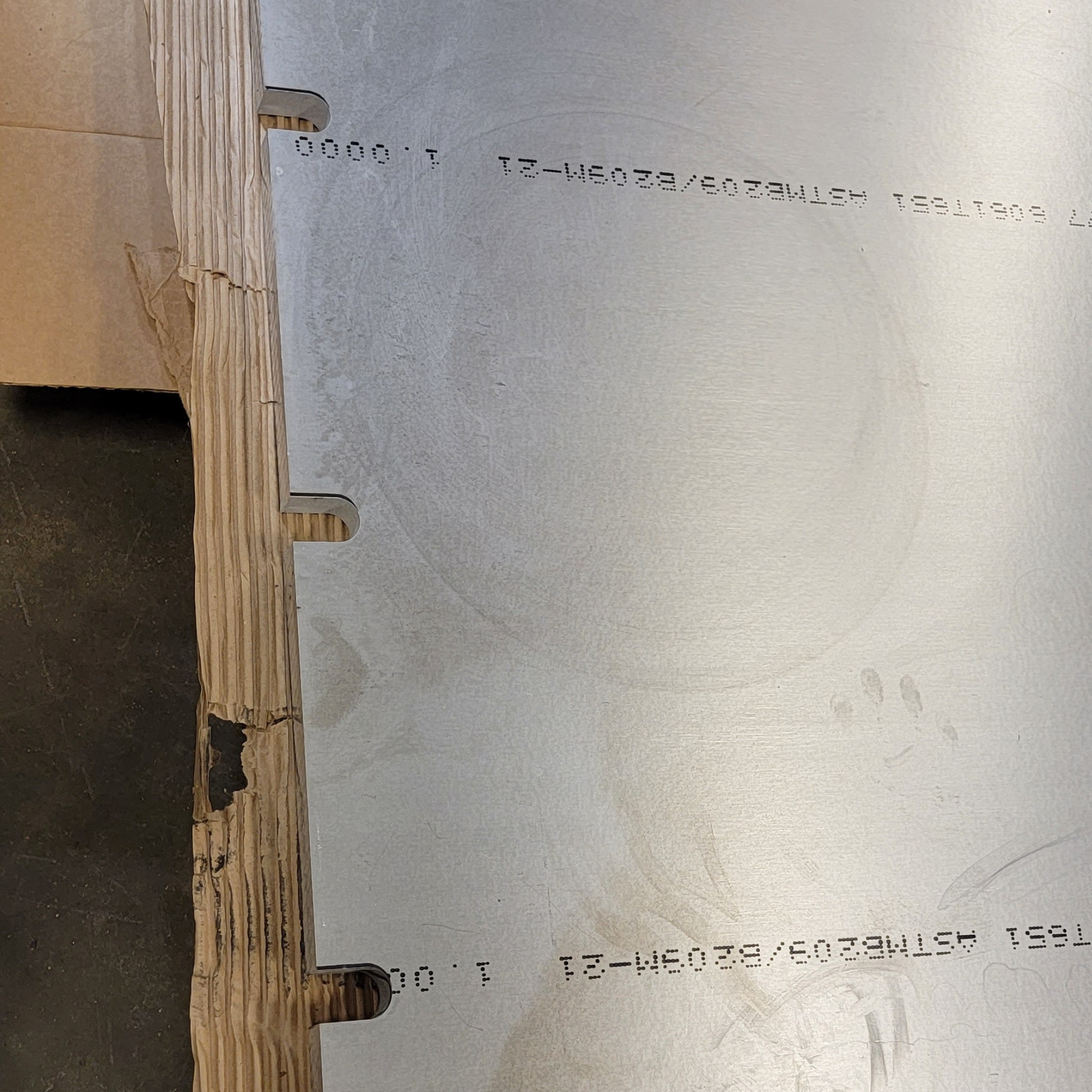

Water jet cutting allows JM Services to cut a WIDE VARIETY of materials.

- 304 stainless steel

- 6061 Aluminum

- A36 Hot Roll

- Over 800 size of Tool Steels

- Sourcing capabilities for other materials

- Plexiglass – Lexan

- UHMW

- Delrin

- DC 53

- DCMX

- Rubber

- Brass

- ET

What type of files do you accept?

JM Services can accept file types of .dwg and .dxf – which are the best – we can also review some other formats.

NOTE: Some simple shapes do not require you to send us a file. Basic shapes such as circles, rings, squares, and triangles can easily be configured in our software. We just need you to tell us the shape desired and the dimensions.